Welcome to my personal webpage!

In this page you will find my research activities.

I am an Associate Researcher at the National Autonomus University of Mexico (UNAM). My research interests are in fluid dynamics, in particular in droplet impact, splashing and jet dynamics. My goal is to use this knowledge in creating solutions for water purification and harvesting.

Recent research projects

For a full list of my publications I invite you to check my google scholar profile.

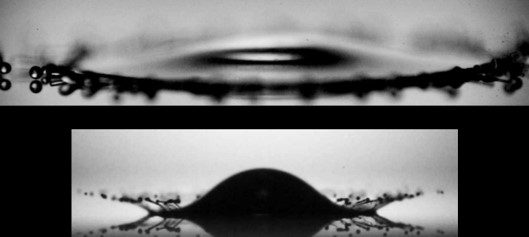

Splashing droplets

A droplet impacting on solid surfaces is a frequently occurring phenomenon found both in our daily lives and in industrial contexts such as in raindrops, inkjet printing and crop-spraying. Of particular importance is understanding and predicting whether a droplet will splash upon impact, i.e., break into a myriad of secondary droplets, spread over or is adhered onto the surface. Consequently, my studies have been focused on predicting the critical conditions for droplet splash on solid surfaces

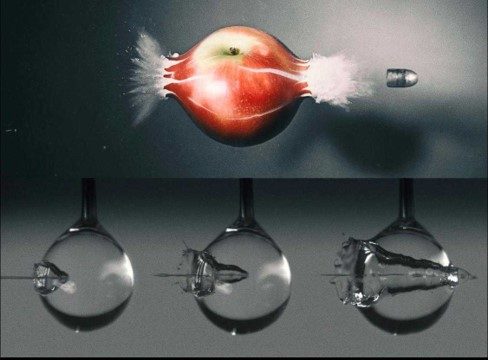

Liquid jet impacting a droplet

The detailed images of a bullet going through an apple are famous. Similarly spectacular is shooting at a liquid droplet. Not with a bullet, but with a focused liquid jet. The results are valuable for a whole new way of injection, without the need for needles. The liquid is the needle! The experiments of impacting a droplet give information about the speed the liquid jet needs to have for traversing the droplet, which help us in the understanding on how to pierce skin.

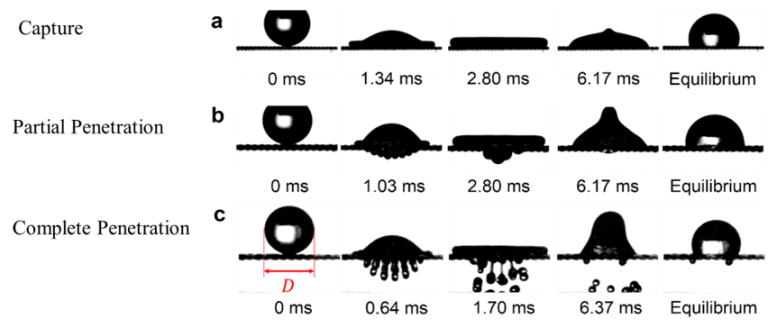

Droplet impact on textiles

Water-repellent clothing is designed to keep water droplets out while letting humidity escape, however our research show that it fails to repel water completely. We determined a critical pore size delimits the two regimes penetration and capture and is inversely proportional to the impact speed, depending on the droplet size and surface tension. For example, for a typical raindrop, the critical pore size for a fabric to avoid complete penetration is approximately 100 μm. This model can also be applied more broadly for design of textiles to protect against more hazardous liquids.

Freezing and melting of water droplets

In this project we explored how droplets freezed and melted depending on the source from which they were collected.

3D printing of liquid latex

We report a new method to reuse discarded tire waste rubber, by making it a component of 3D printed objects. Using liquid latex, we suspend rubber powder to create a colloidal ink suitable for inkjet-based 3D-printing. The in-house designed acoustic-based print-head allows the jetting of the viscous ink across a range of particle loadings. We observe consistent jetting, enabling precise deposition in pre-defined patterns, providing the initial step towards 3D constructs.

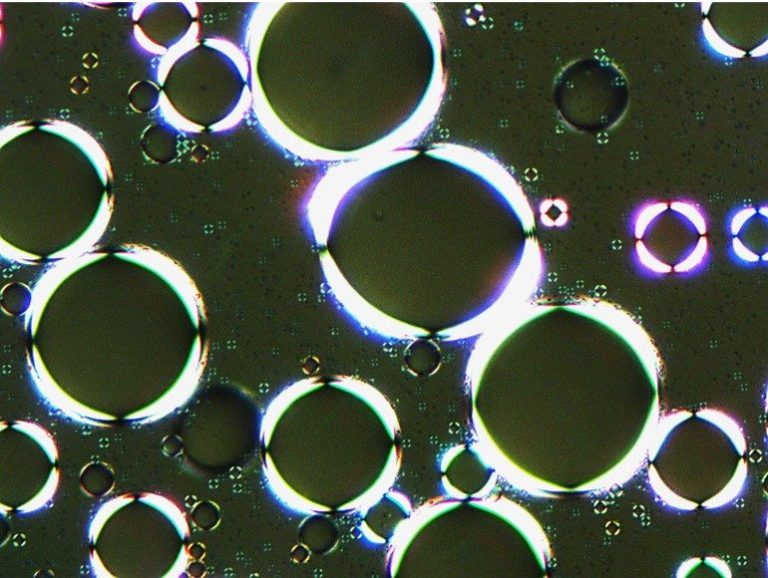

Droplet impact of emulsions

Our study investigates the impact behavior of emulsion droplets—specifically silicone oil, toluene, or heptane in water—on both smooth and photolithographically fabricated microstructured surfaces. We observed that on smooth surfaces, water droplets reached the largest spreading diameter at higher impact velocities, while emulsions with higher dispersed phase concentrations spread less due to greater energy dissipation. Notably, the silicone oil emulsion displayed a transition to non-bouncing on Glaco-coated surfaces, driven by silicone oil infiltration, which created a suction effect. These insights could inform applications like inkjet printing and pesticide spraying, where precise droplet control is essential

©Derechos de autor. Todos los derechos reservados.

Necesitamos su consentimiento para cargar las traducciones

Utilizamos un servicio de terceros para traducir el contenido del sitio web que puede recopilar datos sobre su actividad. Por favor revise los detalles en la política de privacidad y acepte el servicio para ver las traducciones.